Form, Fit, and Function—Built to Spec

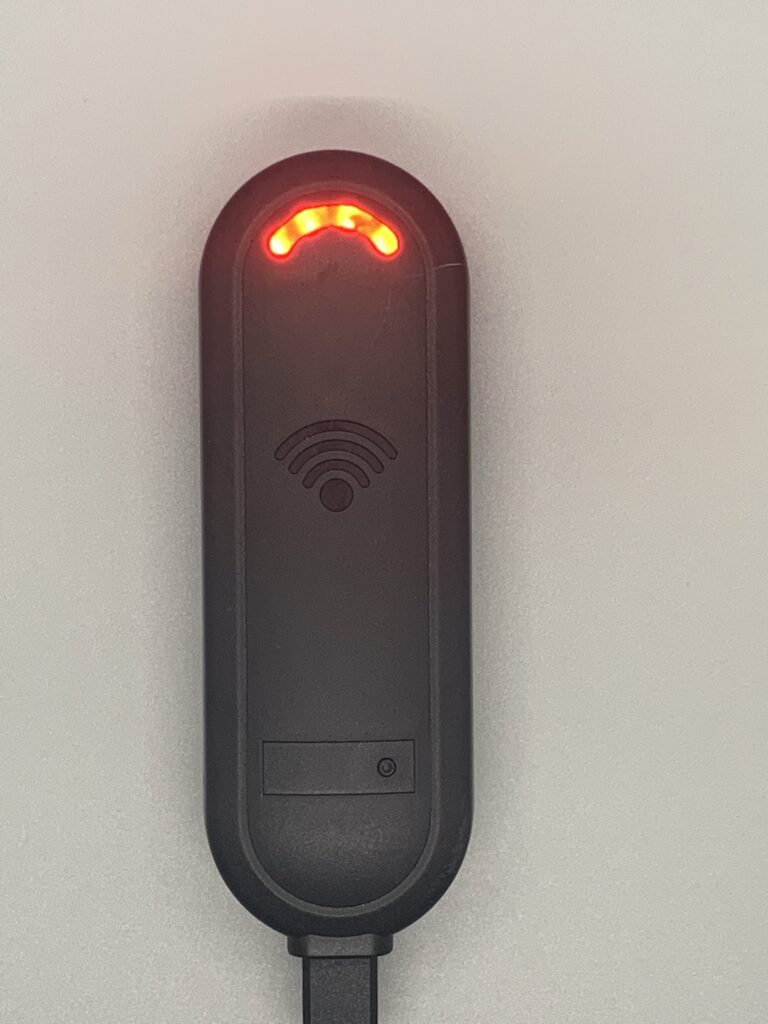

A long-time client came to Design Elevation to develop a line of custom enclosures and mounting systems for new electronics products. Each unit served a different function within the system but shared similar size, shape, and mounting requirements.

Each enclosure had to fit a specific PCB, mount securely to different wall types, and match the company’s clean, professional look—while meeting industry requirements.

We delivered a scalable solution using:

•Injection-molded plastic housings

•Stamped sheet metal for mounting components

•Off-the-shelf parts for cost efficiency

We used 3D-printed and laser-cut prototypes to validate fit, usability, and assembly early in the process—ensuring smooth handoff to production.

The result: a cohesive, production-ready product line designed for efficient manufacturing and a refined, professional appearance in the field.